Four-Axis Automatic Glue Dispensing Machine: Redefining "Non-Contact" Precision Adhesive Application

01 Technical Core: Four-Axis Synergy, Drawing in Air

The heart of the four-axis automatic dispenser lies in its multi-axis motion control system. Through the precise coordination of X, Y, Z linear axes and one rotational axis, the dispensing nozzle can follow any complex three-dimensional path.

This design breaks the limitations of traditional three-axis equipment, proving particularly effective for coating packaging structures with vertical sides or inclined angles. The robot's motion path is optimized by intelligent algorithms, ensuring glue lines remain uniform and consistent—without breaks or bulges—even at high speeds.

02 Key Breakthrough: Non-Contact & Integrated Conveyor

"Non-contact" dispensing is the revolutionary step. Utilizing a high-precision jetting valve, adhesive dots are precisely "shot" onto the workpiece via pneumatic control, with the nozzle maintaining a safe distance from the product at all times.

This eliminates inherent flaws of contact methods like smearing or tailing, making it ideal for handling exquisitely printed surfaces or delicate packaging materials. Product cleanliness on the line improves significantly, while defect rates plummet.

More crucially, the machine features a modular, integrated conveyor. It is not an isolated workstation but a plug-and-play automation unit that can be seamlessly integrated into existing production flows or rapidly deployed to form an independent line, dramatically reducing deployment and line-reconfiguration time.

03 Peak Performance: The Ultimate Solution for Complex Insert Mounting

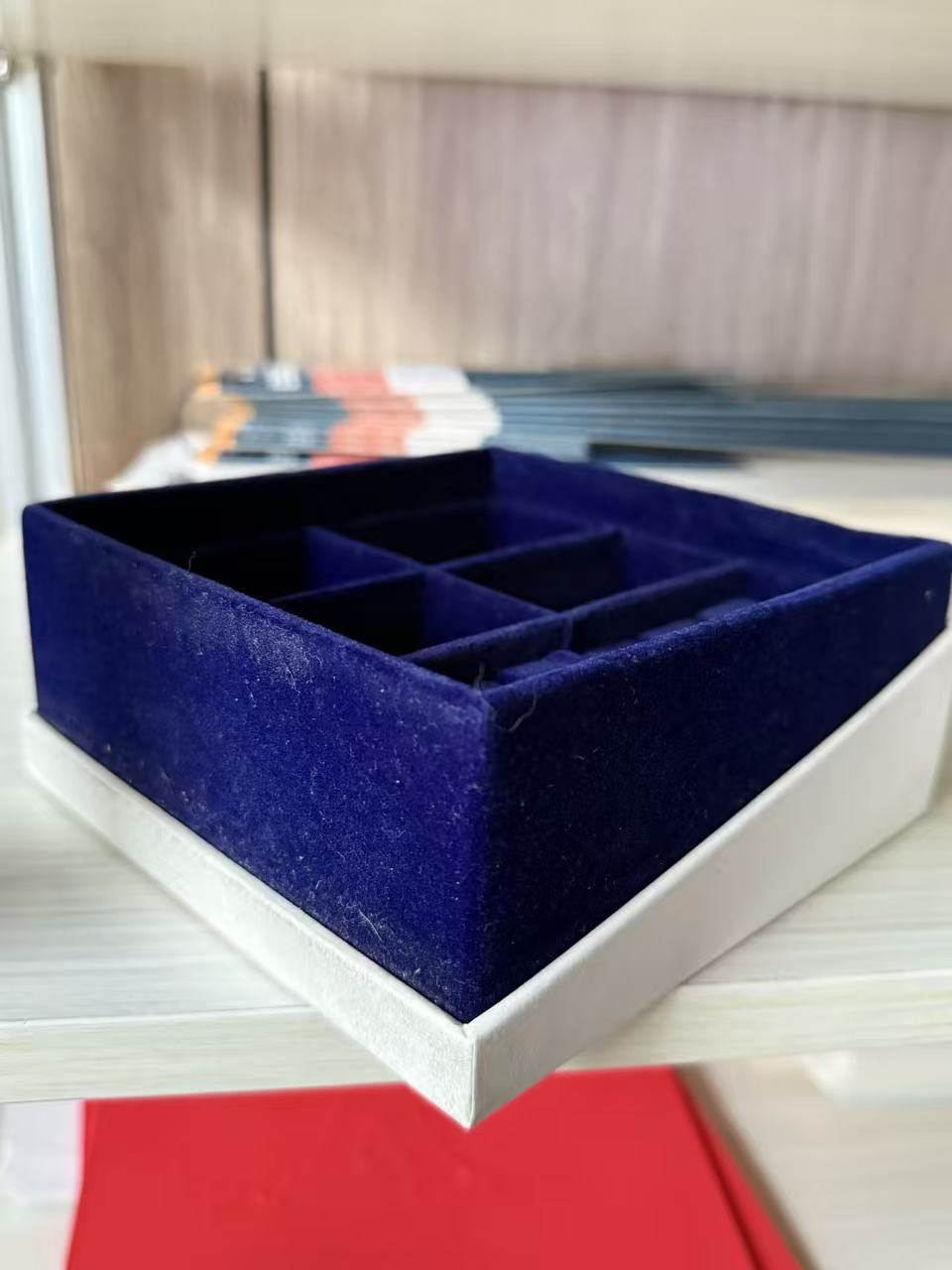

The four-axis dispenser demonstrates irreplaceable advantages in the demanding process of "box insert mounting," which requires extreme precision and bond strength.

Whether for lid-and-base boxes, drawer cases, or irregularly shaped inserts, its flexible robotic arm can accurately apply adhesive to predefined flaps or slots. Assisted by a vision positioning system or precision fixtures, it ensures every insert is bonded firmly and flatly into the box—without warping edges or glue overflow—completely solving the efficiency and quality challenges of manual or semi-automatic mounting.

From a singular dispensing action to an intelligent production node, the four-axis automatic dispensing machine represents not just a technological iteration, but a shift in production philosophy. It makes precise, clean, and efficient "non-contact" manufacturing the standard.

When the last glue dispensing station requiring manual intervention is replaced by an intelligent unit, the entire production line acquires a seamless, fluid rhythm. The glue lines, placed with precision in mid-air, trace the clear outline of the future of automated packaging.

Post time:2025-12-29